Understanding Bioethanol Production: From From Farm to Fire

- Contributors:

- Guillaume Stevelinck

- Published:

The Science of Premium Bioethanol: Why Quality Matters for Your Investment

Agricultural Excellence: How Premium Feedstock Creates Superior Fuel

The foundation of exceptional bioethanol begins in carefully managed farmlands where agricultural practices directly influence fuel quality. For e-NRG bioethanol fuel, corn serves as the primary feedstock, selected for its consistent high sugar and starch content. e-NRG’s premium producers employ sustainable agricultural methods that maximise both yield and purity. Unlike lower-grade alternatives that may use mixed feedstocks or industrial waste, top-tier bioethanol originates from dedicated energy crops such as corn, grown specifically for premium fuel production.

Distillation Mastery: Achieving 96%+ Purity for Clean Burning Performance

The transformation from plant matter to premium fuel requires precise distillation techniques that separate ethanol from water and other compounds, delivering exceptional flame results for ethanol burners. e-NRG bioethanol achieves 99%+ purity through multi-stage distillation processes that eliminate trace compounds responsible for odours, residue, and inconsistent flame characteristics. This high purity level ensures complete combustion, producing only heat, water vapour, and carbon dioxide – the hallmarks of truly clean burning fuel in modern ethanol burners.

Lower-grade alternatives, often containing 85-90% ethanol, burn less efficiently and may produce unwanted byproducts that affect both performance and indoor air quality.

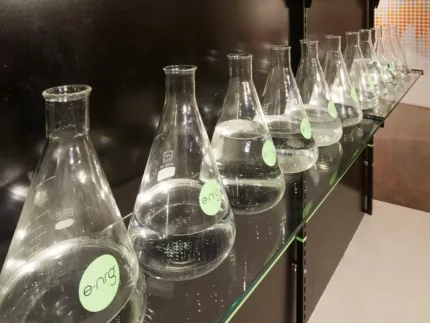

Quality Indicators: What to Look for in Premium Bioethanol Fuel

Recognising premium bioethanol fuel involves understanding several key indicators:

- Clear, colourless appearance signals proper distillation.

- Virtually odourless when cold, with complete odour elimination during combustion.

- Quality assurance includes batch testing for impurities and moisture, not just for combustion characteristics.

Loading image...

Feedstock Quality | Premium Grade | Standard Grade |

Purity Level | 96%+ ethanol | 85–90% ethanol |

Source | Dedicated corn crops | Mixed feedstocks/waste |

Impurity Level | Minimal | Moderate to high |

e-NRG: The Proprietary Advantage That Powers Your EcoSmart Fire

Engineered Excellence: Why Generic Bioethanol Compromises Your Experience

While generic bioethanol may appear similar, the engineering behind e-NRG bioethanol comes from stringent batch control. Each batch is tested for purity, moisture, and specific gravity with traceability at every stage of production, ensuring consistent performance and clean-burning efficiency. This eliminates the variability common with generic alternatives, where inconsistent quality can lead to unpredictable flame behaviour.

Built-in Safety Technology: Flame Arresters and Quality Assurance

e-NRG bioethanol’s safety and reliability come from its pure formulation and careful handling procedures, supporting safer operation of ethanol burners. Batches are comprehensively tested for purity, moisture, and compliance, and are fully traceable, giving peace of mind that generic alternatives cannot match.

Performance Optimisation: Maximum Heat Output with Minimal Maintenance

The superior purity of premium bioethanol translates into maximum heat output efficiency for dedicated ethanol burners, typically delivering 5,000–20,000 BTUs per hour, depending on burner size. Clean combustion also means minimal maintenance requirements, as high-quality fuel leaves virtually no residue in your ethanol burner system.

Regular use of premium fuel can extend burner life significantly compared to generic alternatives.

Loading image...

The Economics of Premium Fuel: Investment vs Operating Costs

Fuel Type | Consumption Rate | Heat Output | Efficiency |

Premium Bioethanol | 0.8 L/hour [0.21 gal/hr] | 15,000 BTUs | 90–95% |

Generic Bioethanol | 1.0–1.2 L/hr [0.26–0.32 gal/hr] | 12,000–13,000 BTUs | 75–85% |

While premium bioethanol commands a higher initial price, the cost per hour of operation for ethanol burners often proves more economical due to higher energy density and complete combustion.

Protecting Your Investment: How Quality Fuel Extends Burner Life

Quality fuel acts as insurance for your ethanol burner investment. Premium bioethanol's clean combustion prevents the buildup of deposits that can clog burner mechanisms or corrode internal components. This protection is particularly valuable in high-end installations where burner replacement costs can reach thousands of dollars.

Heat Output Efficiency: Getting More Warmth from Every Litre

The relationship between fuel quality and heat output efficiency is especially apparent in real-world use of ethanol burners. Premium bioethanol's optimised formulation ensures maximum energy release, achieving 90–95% thermal efficiency compared to 75–85% for generic alternatives. Rooms heat faster, fuel consumption decreases, and overall comfort improves.

Installation Freedom: How Clean Fuel Enables Design Innovation

Vent-Free Operation: Architectural Possibilities Without Compromise

The clean-burning characteristics of premium bioethanol allow ethanol burners true vent-free operation, opening up exciting design possibilities. Unlike gas or wood-burning alternatives that require complex venting systems, bioethanol fireplaces and ethanol burners can be installed nearly anywhere - from penthouse apartments to entertainment rooms - thanks to residue-free fuel and stable storage life.

Indoor Air Quality: Why Low Emissions Matter for Luxury Homes

Premium bioethanol's low emissions profile makes it perfect for luxury residences using ethanol burners, delivering complete combustion with only water vapour and carbon dioxide, mirroring the natural byproducts of human respiration. This means no carbon monoxide or harmful pollutants, safeguarding health and comfort in well-sealed spaces.

Loading image...

© InterContinental Yokohama Pier 8

© InterContinental Yokohama Pier 8 Sustainable Luxury: The Environmental Story Behind Your Fire

Carbon-Neutral Cycle: From Plant to Flame to Atmosphere

Bioethanol, powering today’s finest ethanol burners, represents a truly carbon-neutral heating solution, with combustion releasing only the carbon absorbed by crops like corn during their growth cycle. This closed-loop cycle supports ongoing sustainability and renewable advantages compared to fossil fuels.

Heating Source | CO₂ Emissions | Renewable | Indoor Air Impact |

Premium Bioethanol | Net zero | Yes | Clean burning |

Natural Gas | 2.3 kg CO₂/m³ | No | Requires ventilation |

Wood | Variable | Partially | Particulates/smoke |

Electric (grid) | Varies by source | Partially | None direct |

Future-Proofing Your Home: Sustainable Heating for Conscious Luxury

As regulations tighten and carbon pricing grows, ethanol burners fuelled with bioethanol offer future-proof, sustainable heating for luxury homes. Consistent availability, traceable batch control, and price stability position these fireplaces and burners as leaders in responsible, elegant heating.

The journey from field to fireplace flame is about more than fuel: it’s about design innovation, environmental stewardship, and total peace of mind ensured by high-performance ethanol burners.

-outdoor-elegance-5531-screen.png)

-outdoor-elegance-5531-screen.webp)